Description

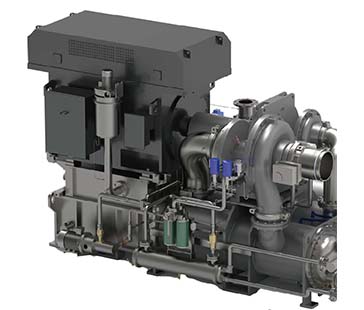

Magnetic suspension centrifugal air compressor

■ Customized order-taking production, customized order-taking according to pressure and ow, providing technical parameters according to requirements

■ ≤500KW, low voltage frequency conversion can be customized, frequency conversion range 20%

Features Introduction

■ Integral assembly, simple structure, compact layout

■ Provide 100% oil-free air

■ The three-stage compressor unit has high e ciency and low operating cost

■ Long-life single-shaft single-impeller rotor structure

■ High e ciency air cooler

■ Automatic control system with microprocessor as the core

■ Constant pressure control and automatic dual control

■ Simple operation, less daily maintenance

■ High-quality and perfect after-sales service and spare parts supply

■ The maintenance time is only one-seventh of the vertical split

■ The inspection of seals, bearings and gears only takes 2.5 hours

■ To check the gear bearing, just lift the upper cover

■ The whole process only takes 2.5 hours

■ High-e ciency ternary ow backward curved impeller

■ Use hard stainless steel material Armco 17.4 pH

■ Optimal parameter design

■ Each impeller is tested for 115% overspeed

■ Unique micro-spline connection, capable of delivering power up to 10,000 kW

■ Assembling and disassembling will not damage the parts

■ Air is sucked in from the air inlet

■ The air is compressed by the rst stage impeller

■ Heat and condensate are taken away in the rst-stage intercooler

■ The air is further compressed by the second stage

■ More heat and condensate are taken away in the second-stage intercooler

■ The air is compressed to the nal pressure in the third stage

■ The air is discharged from the outlet, passes through the aftercooler, and enters the user system after further cooling

Application Field

■ In the petrochemical industry, compressed air is used as an oxidation reaction gas to provide power, etc.

■ In the textile and chemical ber industry, compressed air a ects the quality and hygiene of the fabric, etc.

■ Aerospace industry, engine simulation wind tunnel, pneumatic component test system, etc.

■ Metal smelting industry, heat treatment, instrument gas, air separation nitrogen as protective gas, etc.

Technical Parameters

| Exhaust pressure(MPa) | 0.35~0.46 | 0.35~0.46 | ||||

| Exhaust volume(m³/min) | 73~120 | 113~183 | ||||

| Motor power(KW) | 315~500 | 450~800 | ||||

| Voltage / Frequency(V/Hz) | ||||||

| Air Outlet(mm) | ||||||

| Dimension | Net weight(kg) | 6500 | 10500 | |||

| long(mm) | 4042 | 5620 | ||||

| wide(mm) | 2322 | 2136 | ||||

| high(nn) | 2245 | 2476 | ||||

| Three-stage atmospheric pressure model | C-800 | C-1120 | ||||

| Exhaust pressure(MPa) | 0.7~1.0 | 0.7~1.0 | ||||

| Exhaust volume(m³/min) | 73~120 | 113~183 | ||||

| Motor power(KW) | 400~800 | 630~1120 | ||||

| Voltage / Frequency(V/Hz) | ||||||

| Air Outlet(mm) | ||||||

| Net weight(kg) | 8000 | 12000 | ||||

| Dimension | long(mm) | 4042 | 5620 | |||

| wide(mm) | 2922 | 2576 | ||||

| high(nn) | 2245 | 2476 | ||||

Working Environment

EN

EN  AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS SW

SW GA

GA CY

CY BE

BE IS

IS MK

MK YI

YI HY

HY AZ

AZ EU

EU KA

KA HT

HT UR

UR BN

BN BS

BS CEB

CEB EO

EO GU

GU HA

HA HMN

HMN IG

IG KN

KN KM

KM LO

LO LA

LA MI

MI MR

MR MN

MN NE

NE PA

PA SO

SO TA

TA YO

YO ZU

ZU MY

MY NY

NY KK

KK MG

MG ML

ML SI

SI ST

ST SU

SU TG

TG UZ

UZ AM

AM CO

CO HAW

HAW KU

KU KY

KY LB

LB PS

PS SM

SM GD

GD SN

SN FY

FY